RFID how to improve the efficiency of mould management?

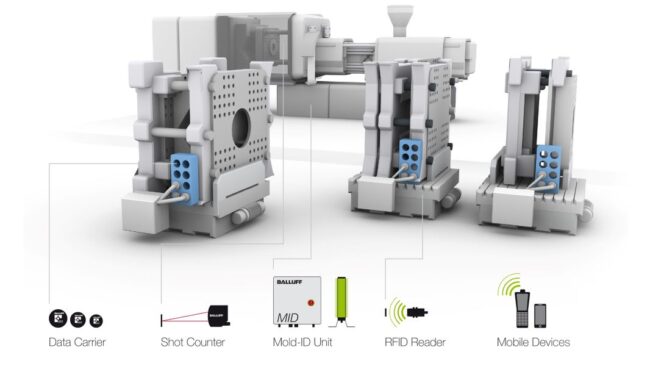

In the manufacturing industry, moulds are the core assets of production, but the traditional management often due to high artificial dependence, data lag, process fragmentation and other issues leading to inefficiency. RFID (Radio Frequency Identification) technology through automated data collection, real-time status monitoring and intelligent decision-making support, to significantly improve the efficiency of the mould…