Why need RFID ?

- Low efficiency of manual entry: relying on manual scanning and registration, which is time-consuming and labor-intensive;

- Prone to errors: barcode scanning needs to be aligned and processed one by one, which is easy to miss or scan incorrectly;

- Inaccurate inventory data: untimely inventory updates can easily cause discrepancies between accounts and actuals;

- Difficult to trace and locate assets: lack of full-process records in the in and out links, and loss and wrong delivery are difficult to check;

- Large inventory workload: low frequency and long cycle of manual inventory, affecting normal operations;

- Many security loopholes: assets are misplaced and abnormal circulation is difficult to detect, which can easily cause losses.

RFID System Functions

1.Automatic warehousing registration

After the items arrive at the warehouse, the RFID reader automatically identifies the items information on the RFID tag and uploads it to the WMS system synchronously without manual entry.

Features and advantages:

Non-contact identification, no need to unpack or align scanning;

Batch reading, can identify multiple items at the same time;

High accuracy, avoid manual entry errors.

Actual benefits:

Shorten warehousing time by more than 70%;

Reduce manual operation intensity and training costs;

Real-time data synchronization, improve inventory accuracy.

2.Efficient inventory

Use RFID handheld terminals or mobile robots to quickly inspect warehouse areas, read tag information in real time, and achieve inventory in seconds.

Features and advantages:

No need for vision or contact, long-distance scanning;

Can read through non-metallic shells such as cartons and wooden boxes;

Automatically compare system data to identify missing or redundant assets.

Actual benefits:

Achieve “unmanned inventory”;

Inventory time is reduced from several days to several hours;

Reduce inventory discrepancy rate and improve audit compliance.

3.Accurate outbound verification

When outbound, the system verifies whether the outbound items match the order information through RFID, and automatically generates outbound orders and logistics information.

Features and advantages:

Real-time verification of order information;

Intercept wrong outbound;

Automatically record outbound personnel, time and item information.

Actual benefits:

Reduce wrong shipment and missed shipment events;

Save verification and recording time;

Improve customer satisfaction and delivery accuracy.

4.Asset life cycle tracking

From the entire process of asset entry, outbound, transportation and return, RFID records the asset status, location and circulation path in real time.

Features and advantages:

Data is synchronized to the background system in real time;

GPS and sensors can be integrated to achieve multi-dimensional tracking;

Support historical trajectory backtracking.

Actual benefits:

Improve asset visualization management capabilities;

Quickly locate problem assets or responsible links;

Support compliance audits and risk management.

5.Intelligent abnormal warning and anti-theft

The RFID system can set logical rules to automatically issue warnings when abnormal asset movement, unauthorized outbound delivery, inventory loss, etc. are detected.

Features and advantages:

Can be linked with the camera to capture;

Support regional restrictions and time period alarms;

Data is pushed to the administrator’s mobile phone or computer in real time.

Actual benefits:

Prevent asset loss and misoperation;

Achieve unattended security management;

Reduce security labor costs.

6.Cargo location management and dynamic positioning

By binding RFID with the WMS system, the items are automatically associated with the cargo location, and the location information is automatically updated when the items move.

Features and advantages:

The system displays the shelves and areas where the items are located in real time;

It can be dynamically presented in combination with maps or 3D warehouse interfaces;

It can realize AGV path planning or fast picking guidance.

Actual benefits:

Greatly improve picking efficiency;

Avoid delays caused by “cannot find items”;

Support refined warehouse distribution management.

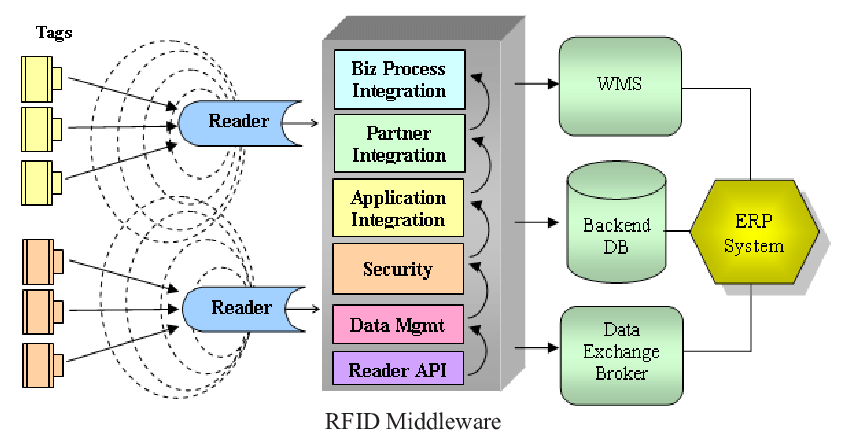

7.Seamless integration with ERP/WMS system

The RFID system can be connected to the company’s existing ERP or warehouse management system through API, interface or middleware to achieve data sharing.

Features and advantages:

Automatically update inventory, financial and order status;

Support visual reports and business analysis;

The system has strong scalability and can be connected with MES, TMS and other systems.

Actual benefits:

Connect information islands and build an intelligent warehousing ecosystem;

Achieve cross-department and cross-system collaboration;

Reduce IT maintenance and system transformation costs.