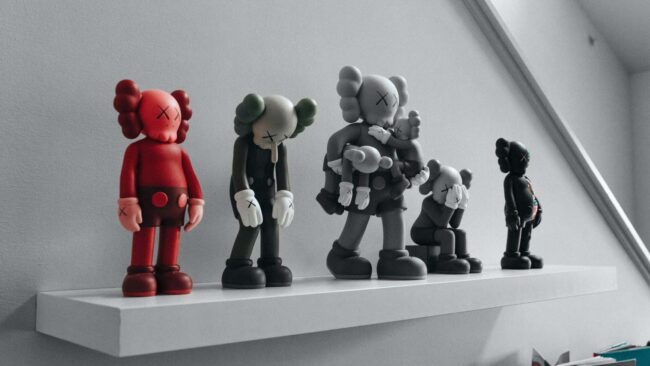

How Can Trendy Toy Brands Use RFID & NFC for Anti-counterfeiting?

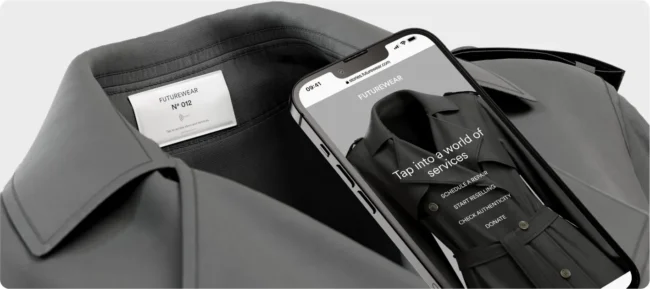

The global trendy toy market suffers from a persistently high counterfeiting rate, continuously impacting the market share of genuine products. Today, intelligent anti-counterfeiting solutions based on RFID (Radio Frequency Identification) and NFC (Near Field Communication) technologies offer a comprehensive and valuable solution to this problem. Traditional anti-counterfeiting methods (such as laser tags and verification codes)…