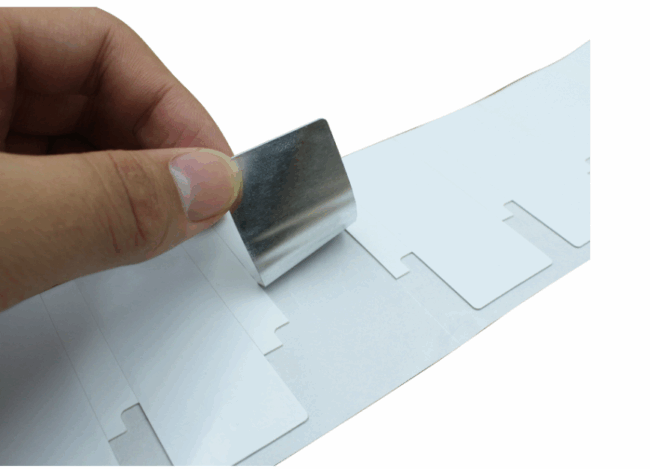

70×30mm RFID Flexible Metal Resistant Tags Empower Industrial Asset Management

From Metal Asset Tracking to a Critical Step in Industrial Digital Transformation In metal-intensive environments such as industrial manufacturing, facility management, and warehousing and logistics, visualization and management of assets is increasingly important. However, the strong interference of metal to RF signals brings challenges to traditional RFID systems. the emergence of RFID flexible anti-metal tags,…