Manuel takibe elveda deyin ve RFID ile otomatik kalıp yönetiminin kilidini açın

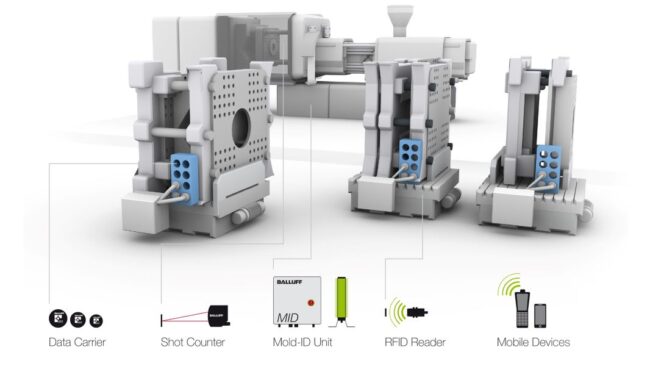

In automotive manufacturing, electronic injection moulding, metal processing and other production scenarios that rely on moulds, the traditional manual ledger, paper labels or barcode tracking methods are becoming a bottleneck for efficiency improvement. By giving moulds a ‘digital identity’, RFID allows mould management to be upgraded from ‘manual experience-driven’ to ‘data automation-driven’, unlocking the key…