Попрощайтесь с ручным отслеживанием и разблокируйте автоматическое управление пресс-формами с помощью RFID

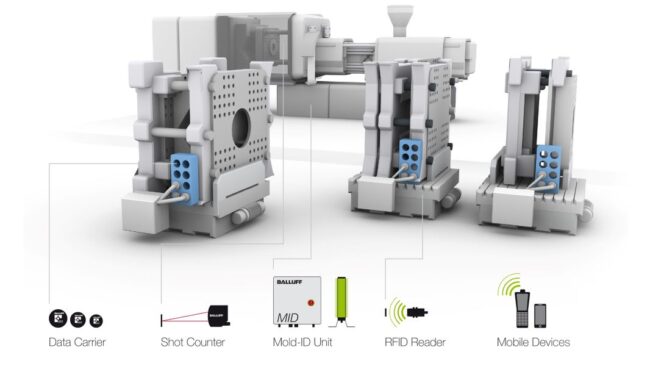

In automotive manufacturing, electronic injection moulding, metal processing and other production scenarios that rely on moulds, the traditional manual ledger, paper labels or barcode tracking methods are becoming a bottleneck for efficiency improvement. By giving moulds a ‘digital identity’, RFID allows mould management to be upgraded from ‘manual experience-driven’ to ‘data automation-driven’, unlocking the key…