RFID in der Werkzeug- und Werkzeugverwaltung in der Weisheit der Anwendungen

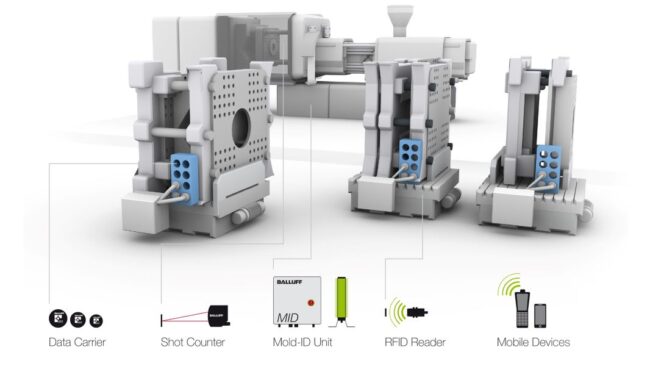

In the discrete manufacturing industry, moulds and tooling are the ‘skeleton’ and ‘muscle’ of the production chain, jedoch, the traditional management approach has long faced asset loss, loss of control of the state, maintenance of inefficiency and other pain points.The depth of application of RFID technology, by giving moulds and tooling a ‘digital identity’ Ist…